The largest civil area of the Institute is the design, serial production and maintenance in operation of instrumentation & control (I&C) systems for industrial and power-generating facilities.

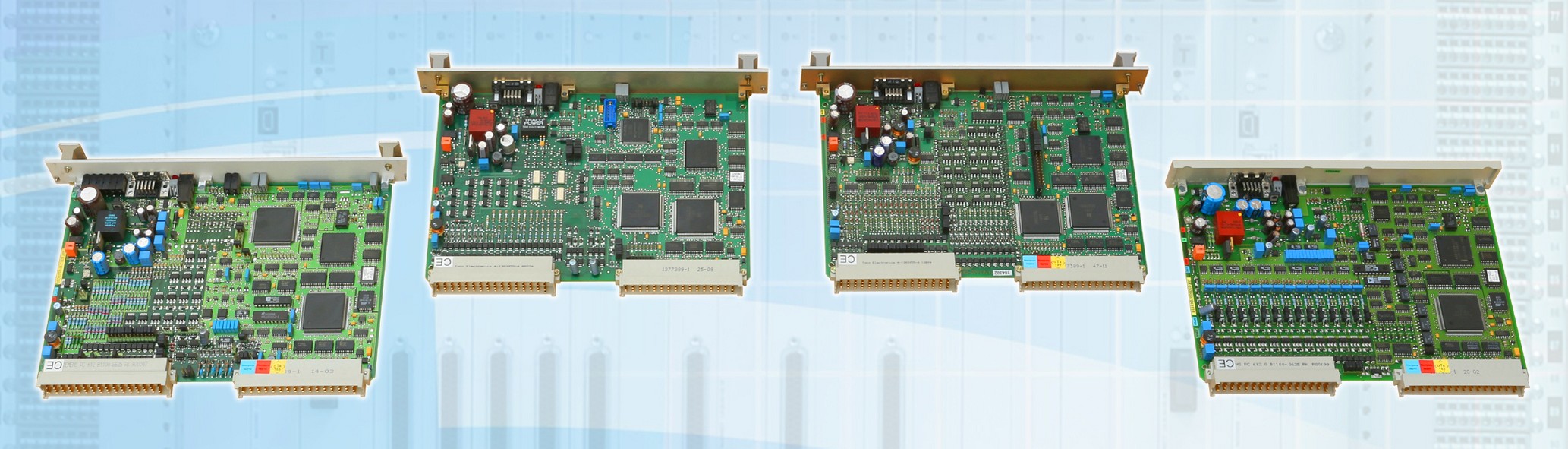

SHC components: modules, crate, cabinet

SHC components: modules, crate, cabinet

The control systems produced at VNIIA are based on the software & hardware of the TPTS type, developed and continuously improved by our experts. All the equipment, assemblies, devices, including the printed boards and modules with surface mounting, are produced in Russia according to the design documents based on the domestic regulations and standards. The components used are the highly reliable semiconductor devices from the world’s leading companies in this area.

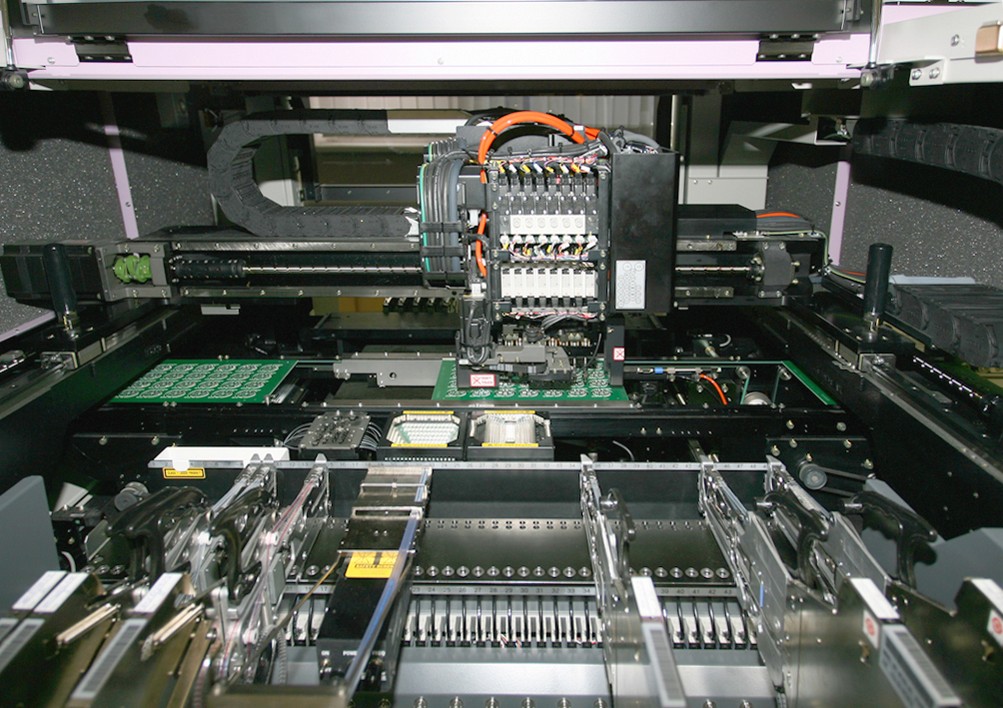

Electronic modules production shop

Electronic modules production shop

Instrumentation & control systems produced by VNIIA comply with the most stringent international requirements and compete with the similar systems on the world’s market.

TPTS-SB Equipment

Specialists of the Institute independently developed and implemented several generations of I&C, the latest of which exceed the best foreign equipment on a number of parameters.

The equipment has much larger range of automation tasks, including special ones, an advanced communications system based on standard industrial protocols is implemented, performance is significantly enhanced, system design capable of handling thousands of signals with the monitoring cycle for each signal in the ms range is ensured.

TPTS Equipment Test Site

TPTS Equipment Test Site

All generations of I&C equipment (TPTS, TPTS-E TPTS-EM, TPTS-NT, TPTS-SB) are certified by the Russian RosTechNadzor for application at NPP.

The quality system that covers the design, production and maintenance of TPTS equipment has an international certificate annually reconfirmed by TÜV-SERT European audit company.

High-performance machine for automatic installation of components on PCBs

High-performance machine for automatic installation of components on PCBs

The Institute completed the development of TPTS-SB software and hardware meant for safety systems of nuclear reactors. Joint use of TPTS-NT and TPTS-SB systems allows covering of all automation at nuclear and thermal power plants.

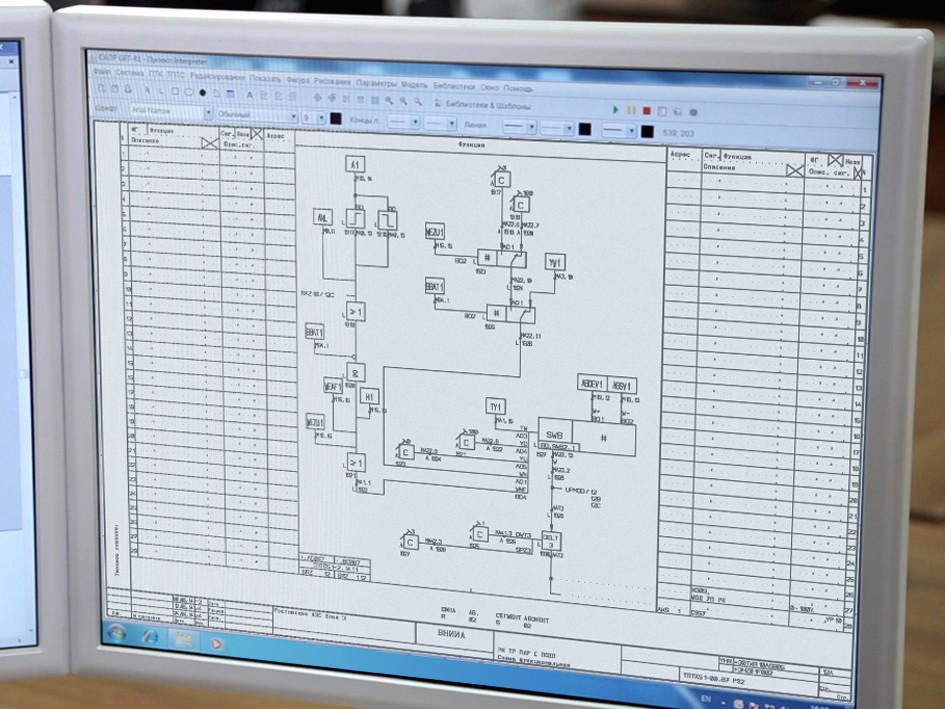

Engineering system for design of software and hardware

Engineering system for design of software and hardware

I&C based on TPTS of several generations has proved itself at the Russian thermal power plants (Berezovskaya power plant – 2 units per 800 MW, Perm power plant – 2 units per 800 MW Kaliningrad power plant-2, Ivanovskaya power plant, Mutnovskaya geothermal power plant, etc.).

I&C designed by VNIIA is competitive on the world market. In particular, the I&C for the following thermal power plants were designed: Suizhong (China) – 2 units per 800 MW, Kostolac (Serbia), Ghorazal (Bangladesh), Zmijev (Ukraine), Aksu (Kazakhstan) – 2 units, Harta and Yuzifia (Iraq) – 2 units each, Obra (India) – 2 units, etc.

Kalinin NPP Kudankulam NPP (India)

Kalinin NPP Kudankulam NPP (India)

All projects were won at tenders with the participation of the Russian and foreign suppliers (Emersson, ABB, etc.). In total number of thermal power units equipped by the Institute with I&C is more than 40 in 8 countries.

Suizhong TPP

Suizhong TPP

Successful operating experience of I&C supplied by the Institute to more than 10 NPP units of in Russia, India is of great importance. In particular, these include units 3 and 4 of Kalinin NPP, units 2, 3 and 4 of Rostov NPP, units 1 and 2 of Novovoronezh NPP, unit 4 of Beloyarsk NPP, units 1 and 2 Kudankulam NPP (India).

Over 2,000 instrumentation cabinets containing more than 60,000 electronic modules of high complexity were delivered. Currently the design effort is under way on I&C for 7 other NPPs in Russia and abroad.

The high operational quality and technical performance of TPTS equipment allow using it almost in all any kind of industry for automatic of process, including the critical and nuclear hazardous facilities.

Commissioning of TPTS Equipment at NPP

The equipment is remarkable for its record reliability – real operation demonstrated that mean-time-between-failures for any type of module with more than 1,000 components is over 70 million hours.

Electronic modules for TPTS equipment

Electronic modules for TPTS equipment

Designed and manufactured I&C systems are thoroughly tested at the test site in presence of the Customer and the supervisor authority. During the testing, the operational staff of the Customer is trained.

VNIIA delivers the complete system, carries out the installation and commissioning on the ‘turn-key’ basis, and provides warranty and post-warranty maintenance.